Selected Publications

See my Google Scholar for a full list.

(#: corresponding author)

Journal Paper

-

Yunan Wang, Chuxiong Hu#, Zeyang Li, Shize Lin, Suqin He, Yu Zhu

IEEE Transactions on Automatic Control, Full Paper, 2025

Also presented in IEEE CDC, December, 2025 (Coming Soon)

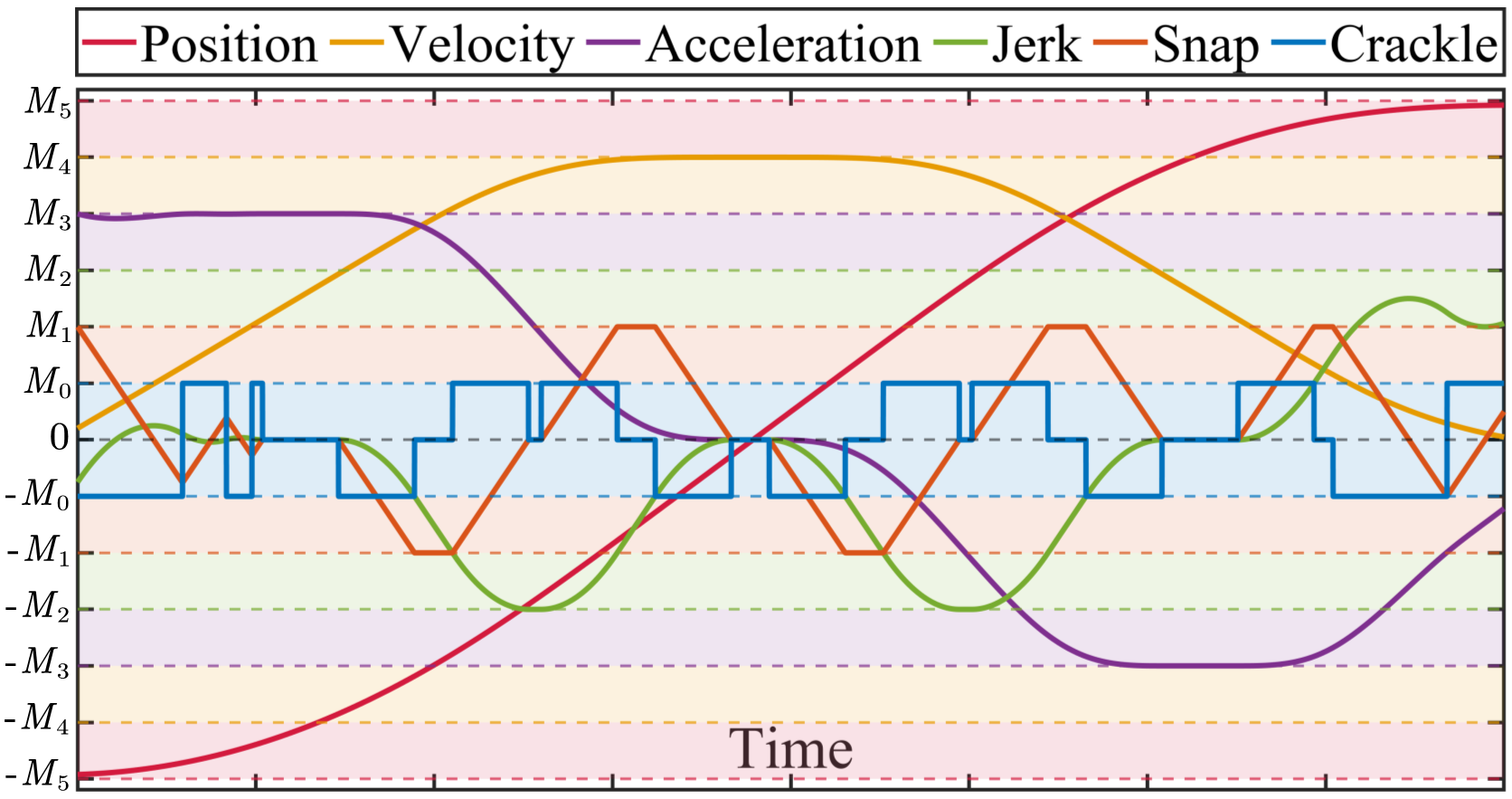

Time-optimal control for high-order chain-of-integrator systems with full state constraints remains a fundamental problem in optimal control domain, yet not to be resolved. It requires a trajectory within minimum time under assigned upper bounds of position, velocity, jerk, etc. There have been few mature methods with the ability of planning feasible trajectories of order n≥4 with non-zero boundary conditions as follows:

Figure 1. A fifth-order trajectory planned by MIM.

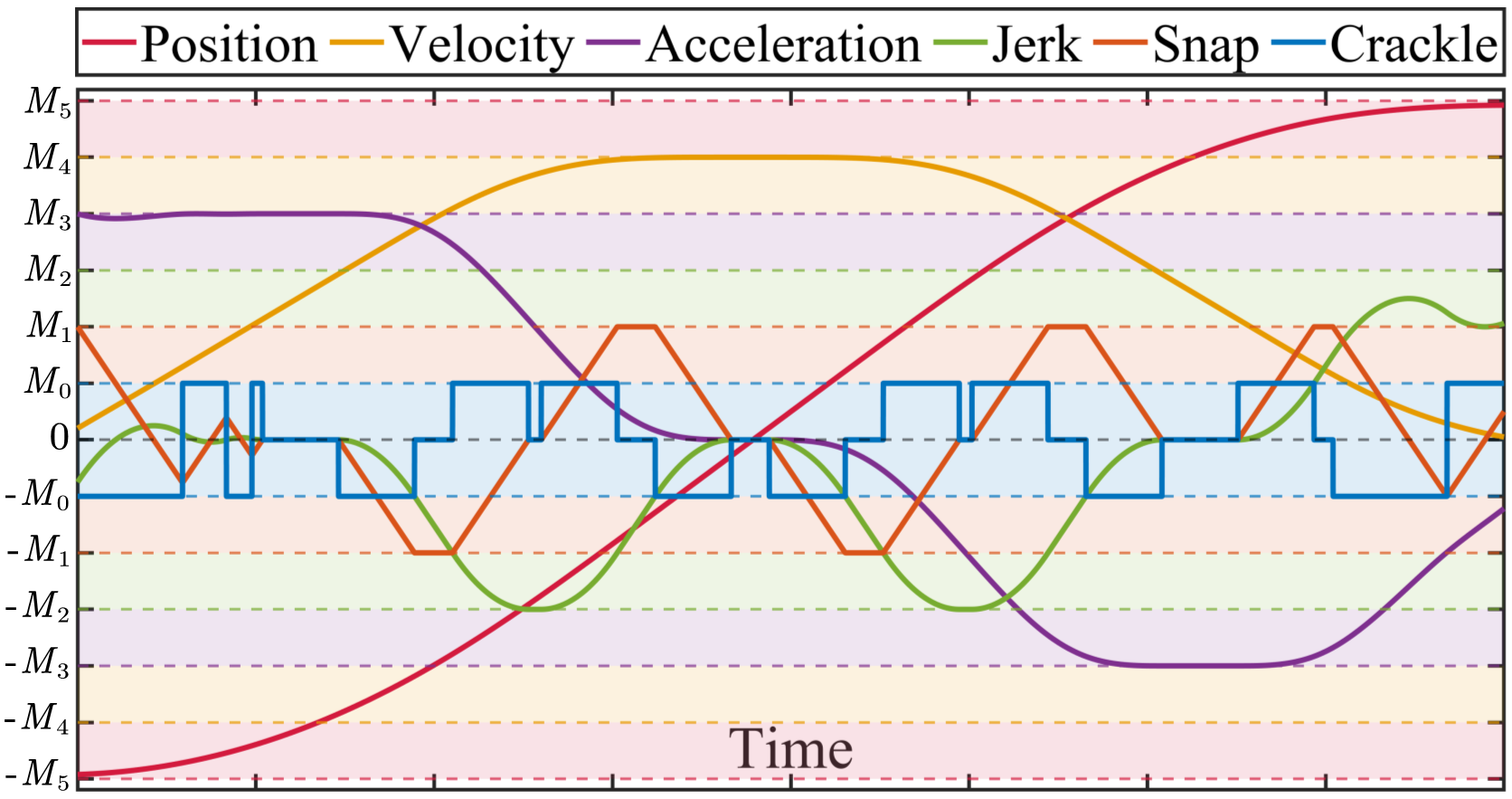

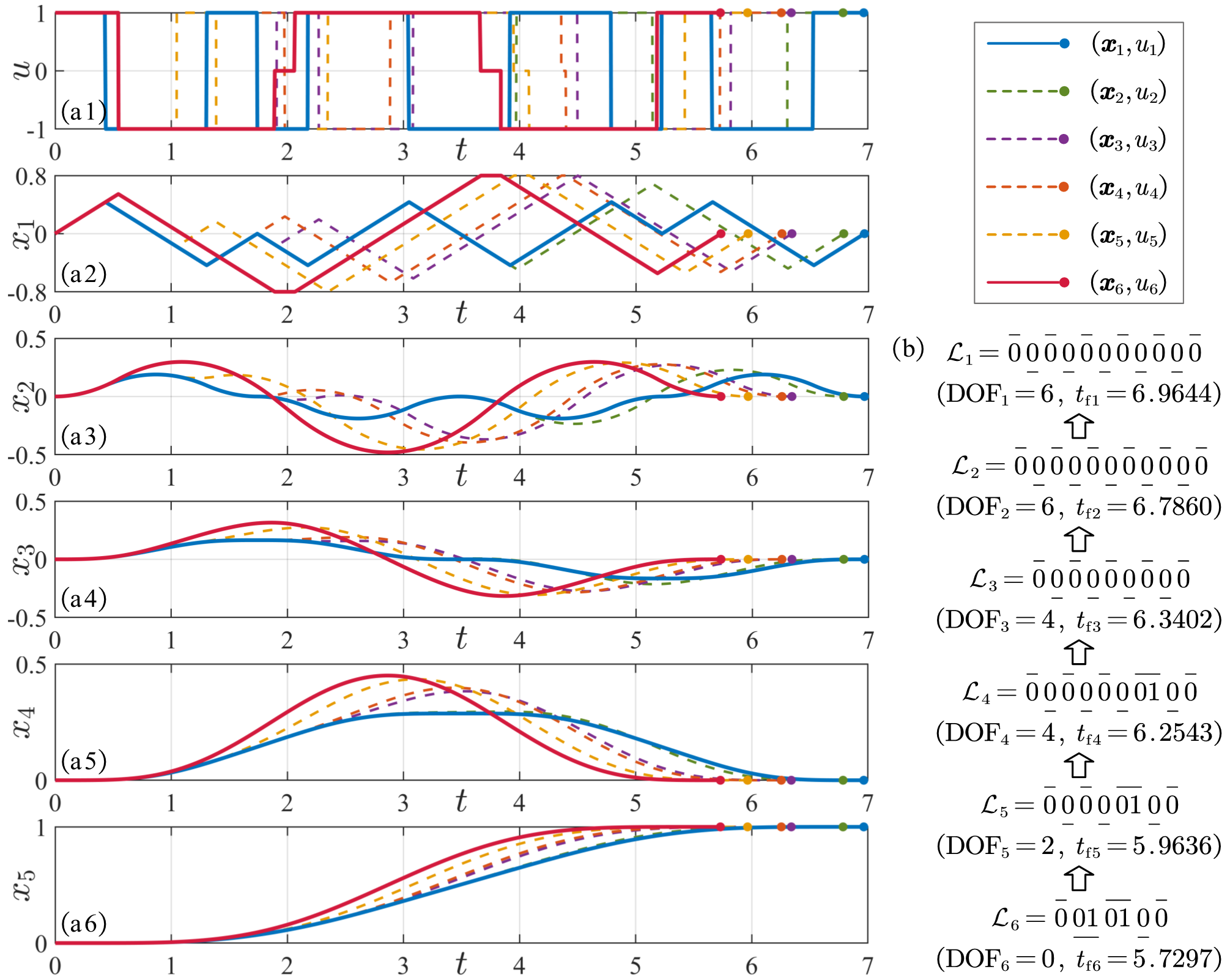

This paper establishes an original notation system and special theoretical framework called the augmented switching law (ASL), which consists of unconstrained arcs, constrained arcs, and tangent markers. ASL provides a compact algebraic representation for switching manifolds and definite conditions for the problem, as shown in the following figure. The sign and dimension properties of the ASL are derived. Guided by the geometric and algebraic results, this paper also develops an efficient algorithm, namely manifold-intercept method (MIM). MIM can plan time-optimal trajectories of order n≤3 and near-optimal trajectories of order n≥4. For 4th-order problems, MIM achieves a computational time reduction of two orders of magnitude compared to baselines, while improving computational accuracy by more than 90%.

Figure 2. Time-optimal switching manifolds.

-

Yunan Wang, Chuxiong Hu#, Zeyang Li, Yujie Lin, Shize Lin, Suqin He

IEEE Transactions on Automatic Control, Full Paper, 2025

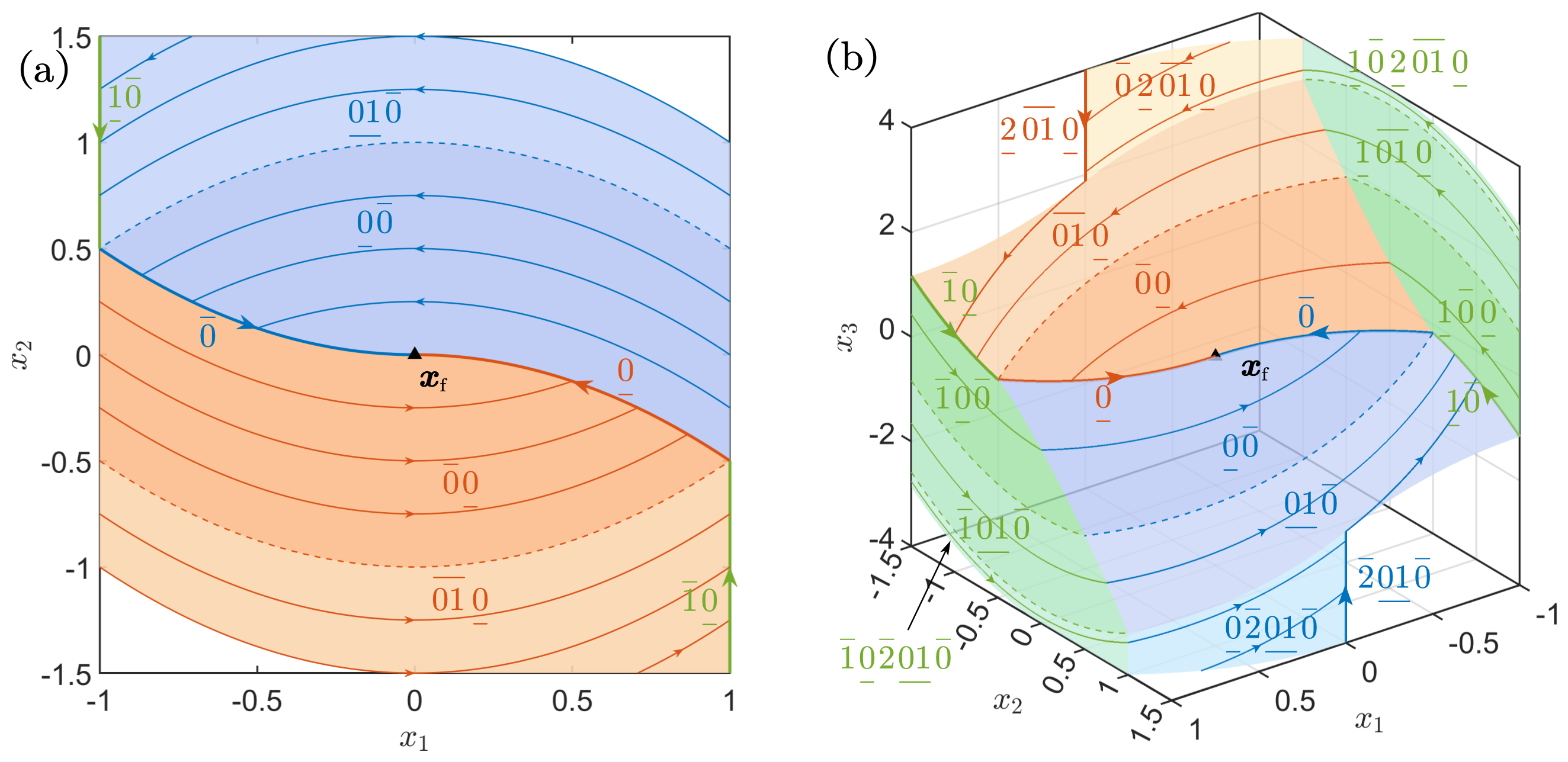

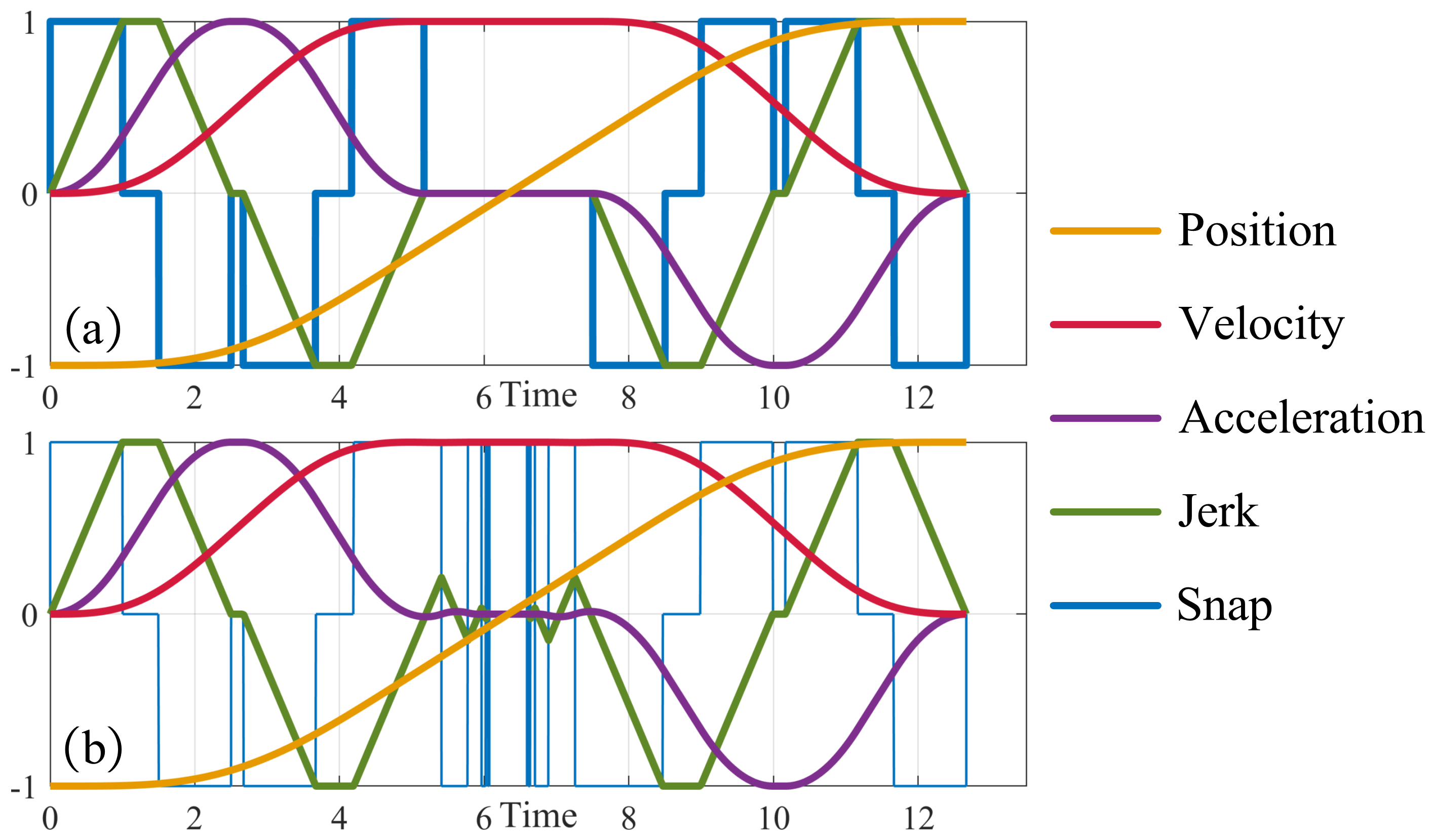

For a long time, it is widely accepted that S-shaped profiles should be the time-optimal solution for the above problem under some proper conditions, as shown in Figure 1(a). However, this paper points out that it is a misconception. For the first time, the fourth-order strictly time-optimal trajectory is provided, as shown in Fig. 1(b). The chattering phenomenon occurs that the optimal control (snap) must switch for infinitely many times in a finite time period.

Figure 1. (a) S-shaped profile. (b) Time-optimal profile.

Furthermore, existing mathematical tools based on Lagrangian manifolds cannot apply to high-order problems due to the singular Hamiltonian of order ∞. I establish a special theoretical framework for the considered problem of order n, providing novel findings on the uniqueness of chattering state constraints, the upper bound on switching times in every arc, and limiting behaviors of states/costates.

-

A Novel State-Centric Necessary Condition for Time-Optimal Control of Controllable Linear Systems Based on Augmented Switching Laws

Yunan Wang; Chuxiong Hu#; Yujie Lin; Zeyang Li; Shize Lin; Suqin He

Conditionally Accepted by IEEE Transactions on Automatic Control, Full Paper, 2025

The concept of ASL is generalized to time-optimal control for general single-input controllable linear systems. Without dependence of costate information, a novel state-centric necessary optimality condition is developed, asserting that the Jacobian matrix induced by the ASL is not full row rank. Note that costates are usually unobservable in practice, especially when the trajectory is not planned by costate-based optimization; hence, the developed condition can determine the optimality of a given trajectory. Furthermore, it can be used to optimize feasible bang-singular-bang trajectories, as shown in Figure 1.

Figure 1. Optimization of a fifth-order trajectory based on ASL.

The developed state-centric necessary condition is applied in reverse to chain-of-integrator systems, resulting in some novel conclusions that are challenging to prove through traditional necessary conditions based on Pontryagin's maximum principle. For example, a recursive equation of junction time is reasoned in the chattering phenomena induced by second-order constraints in high-order problems. A consistent upper bound on the number of arcs is determined, while case-by-case analysis is necessary in traditional methods.

-

Yunan Wang, Chuxiong Hu#, Ze Wang, Shize Lin, Ziyan Zhao, Wenxiang Zhao, Kehui Hu, Zhongyi Huang, Yu Zhu, Zhigang Lu

Robotics and Computer-Integrated Manufacturing, 2023

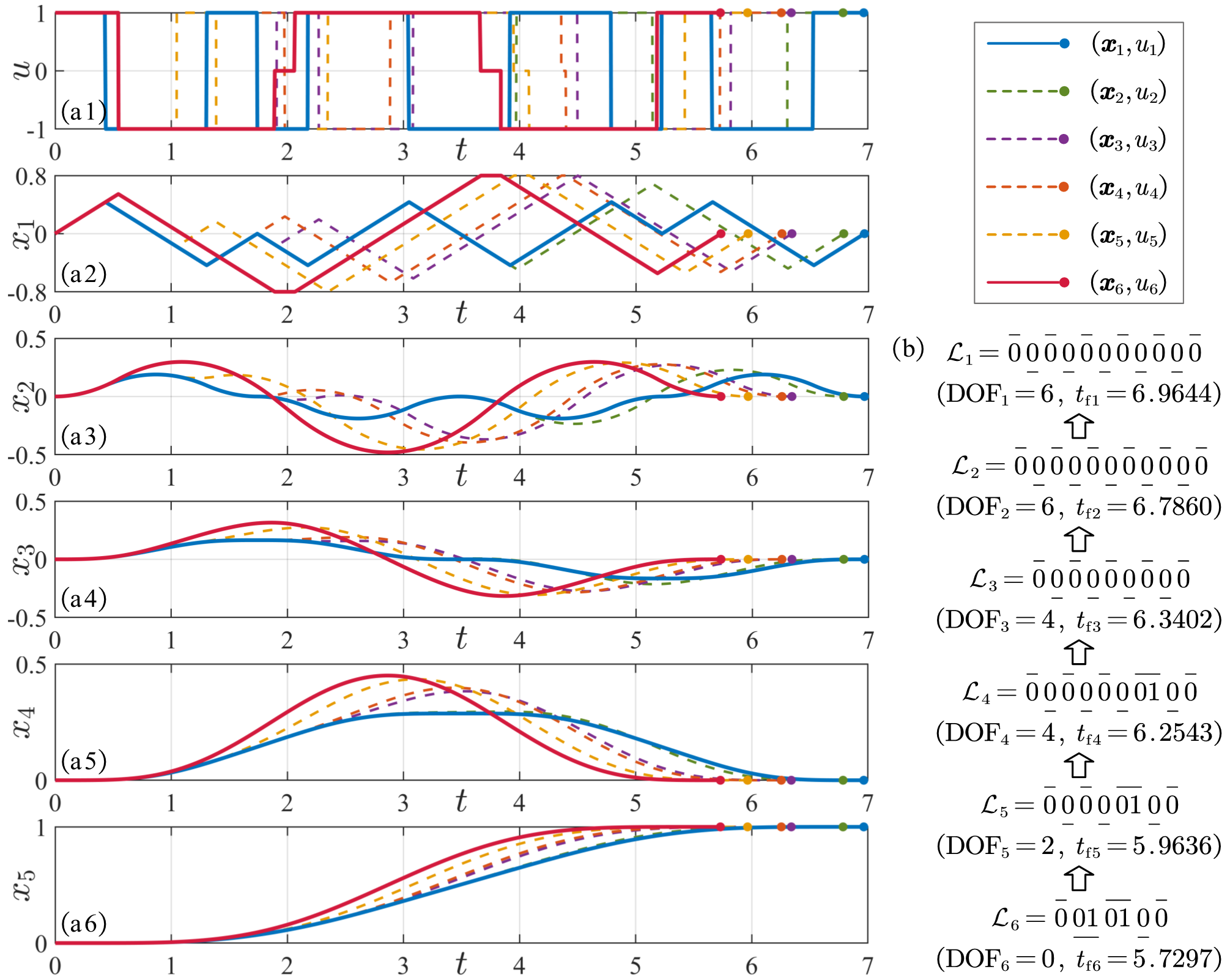

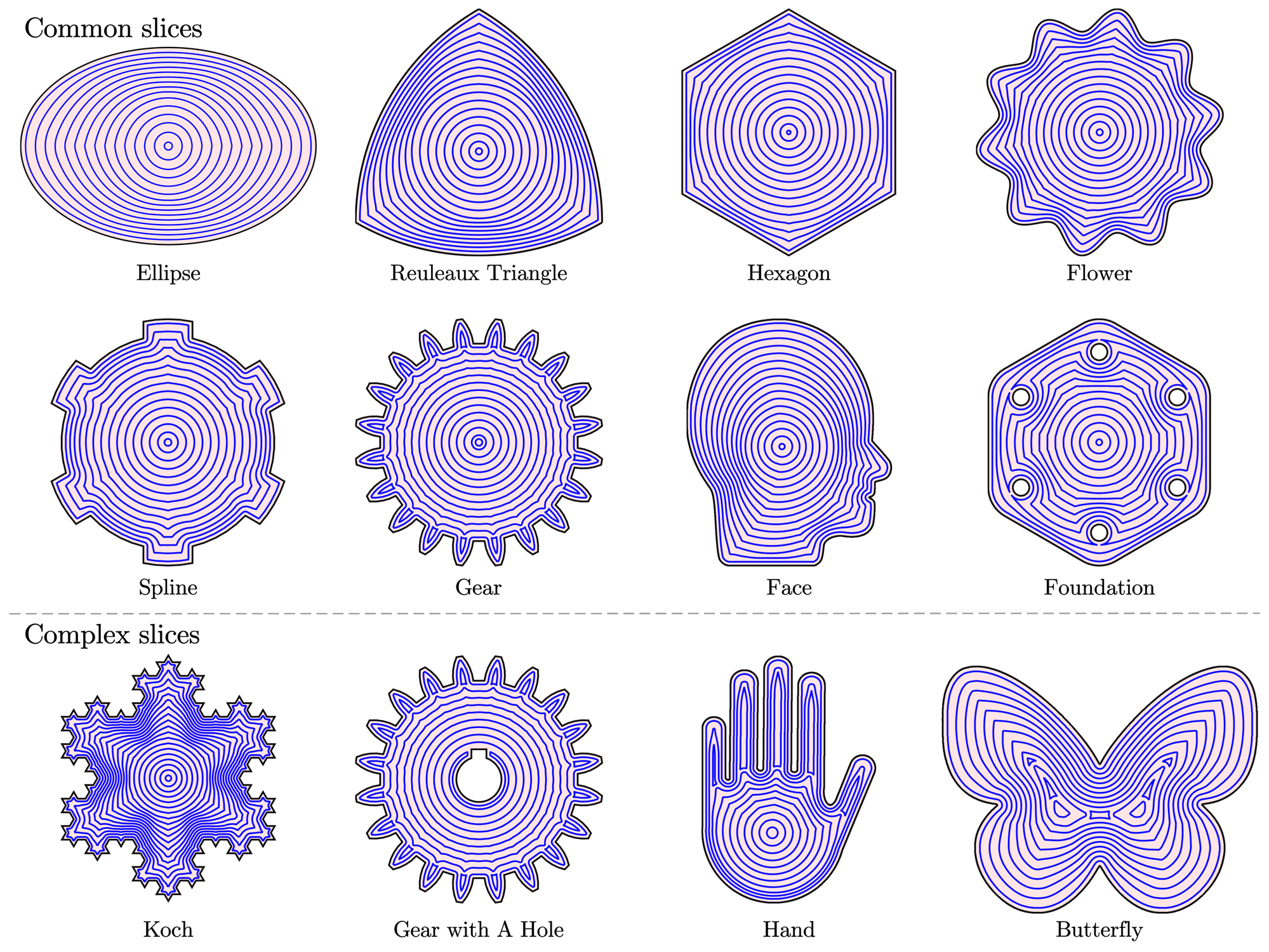

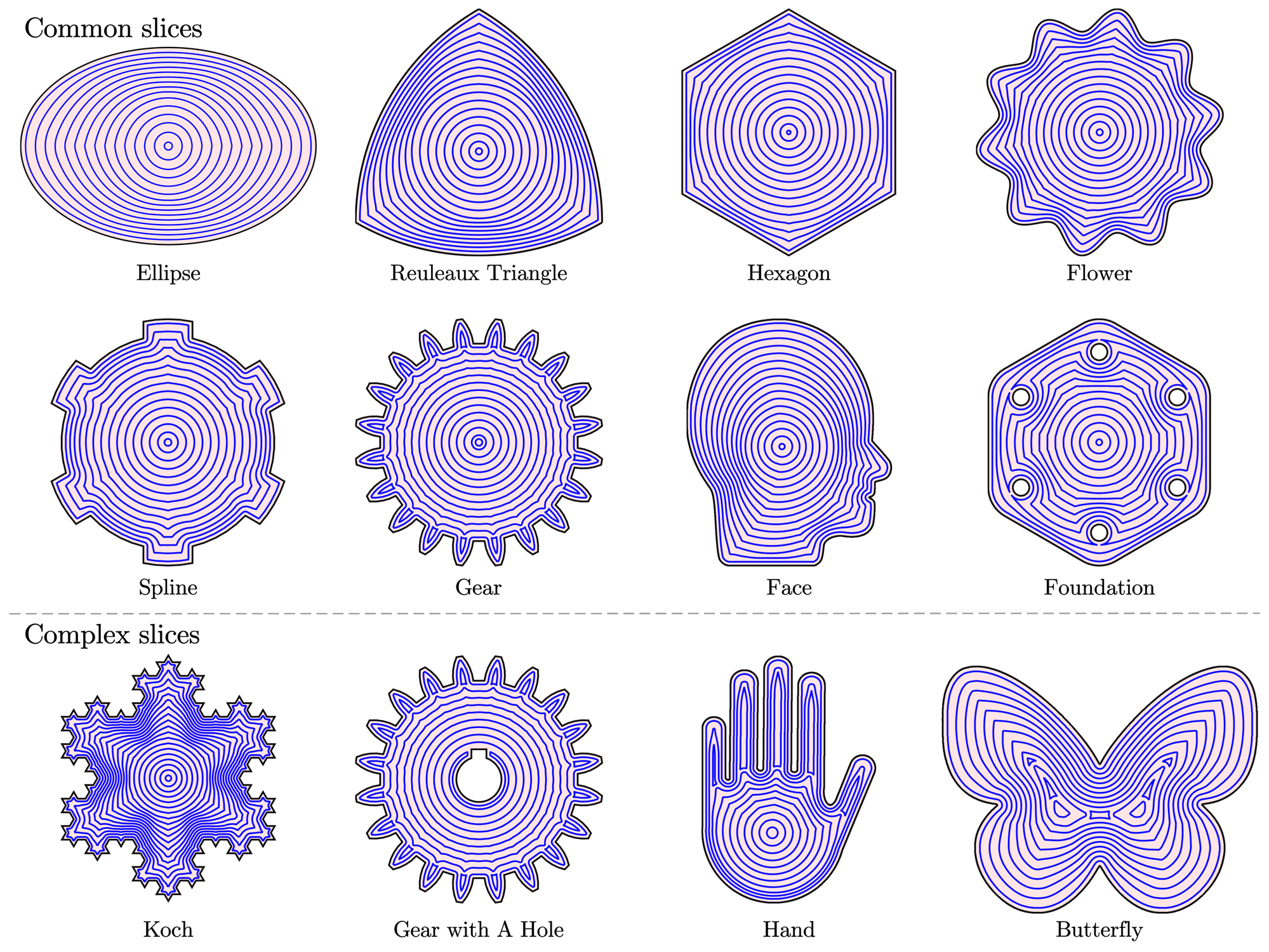

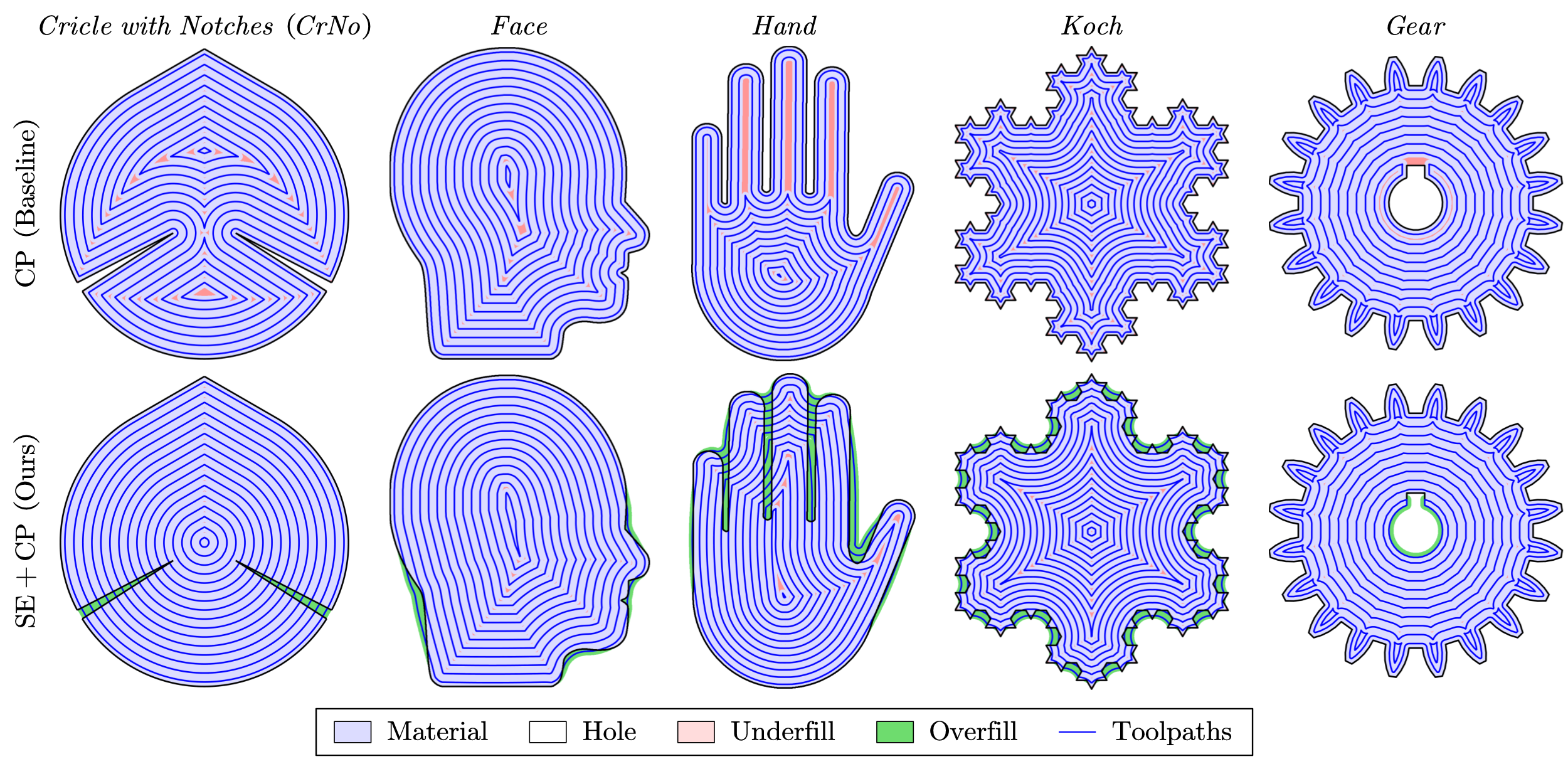

In additive manufacturing (AM), toolpaths have significant impacts on printing quality and efficiency. Despite the potential to avoid underfill, most existing non-equidistant (NE) toolpaths does not support user-designed shapes. I develop an optimization-based framework for NE toolpath planning, resulting in IQOP which optimizes the isoperimetric-quotient for high smoothness. The non-convex problem is transformed into sequential convex programming, and the well-posedness is guaranteed by the proposed unilateral rolling circle (URC) method. In other words, URC can avoid the common self-intersection of AM toolpaths with properties of smoothness, regularity, enclosure, and maximality. As shown in Figure 1, IQOP can be applied to different slices with complex shapes and topological structures, where toolpaths are gradually transformed into smooth circles.

Figure 1. IQOP in different slices.

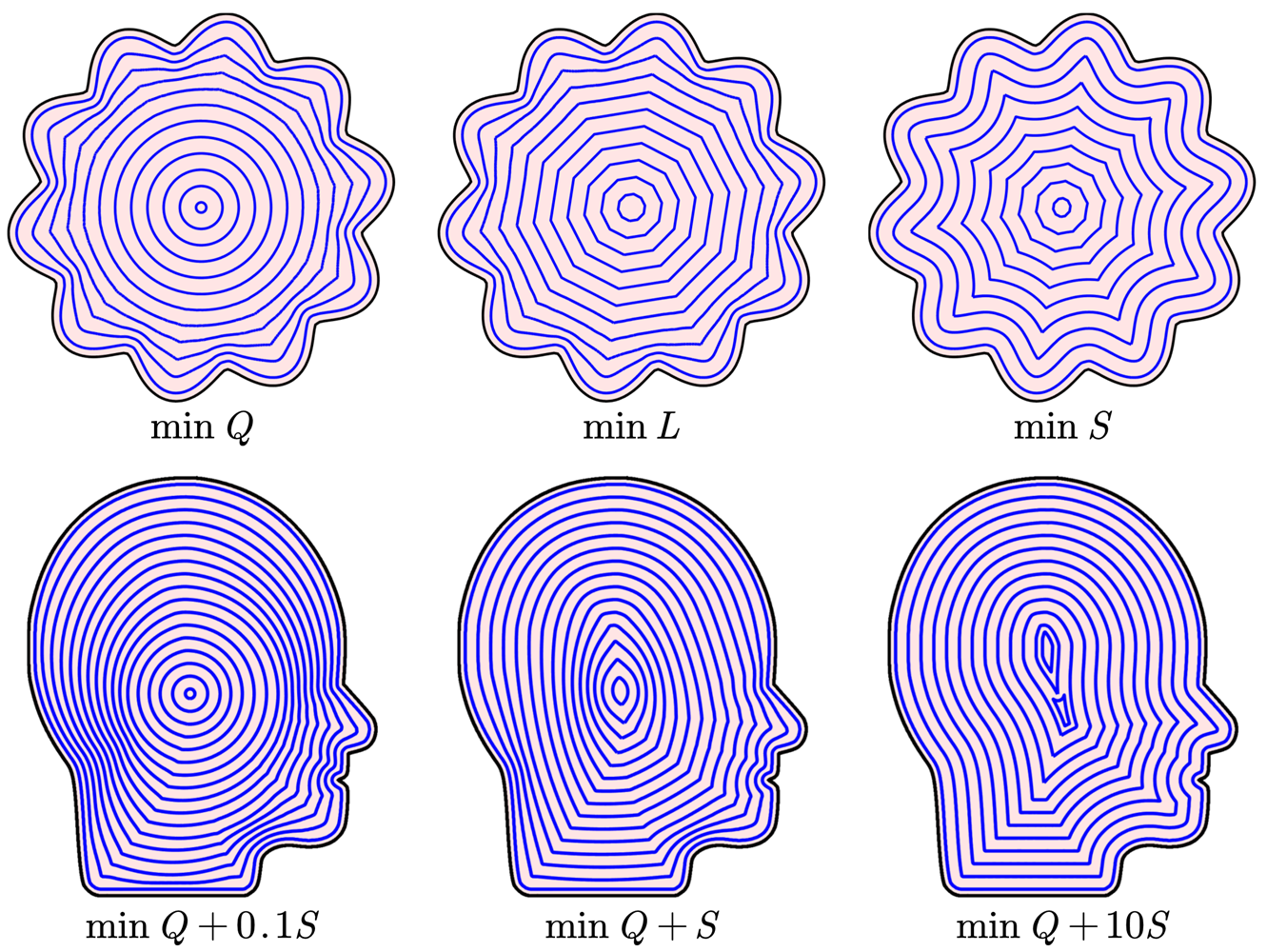

Applied with different objective functions, IQOP can also perform various user-specified toolpath behaviors, which was challenging in existing works, as shown in Figure 2.

Figure 2. IQOP with different objective functions.

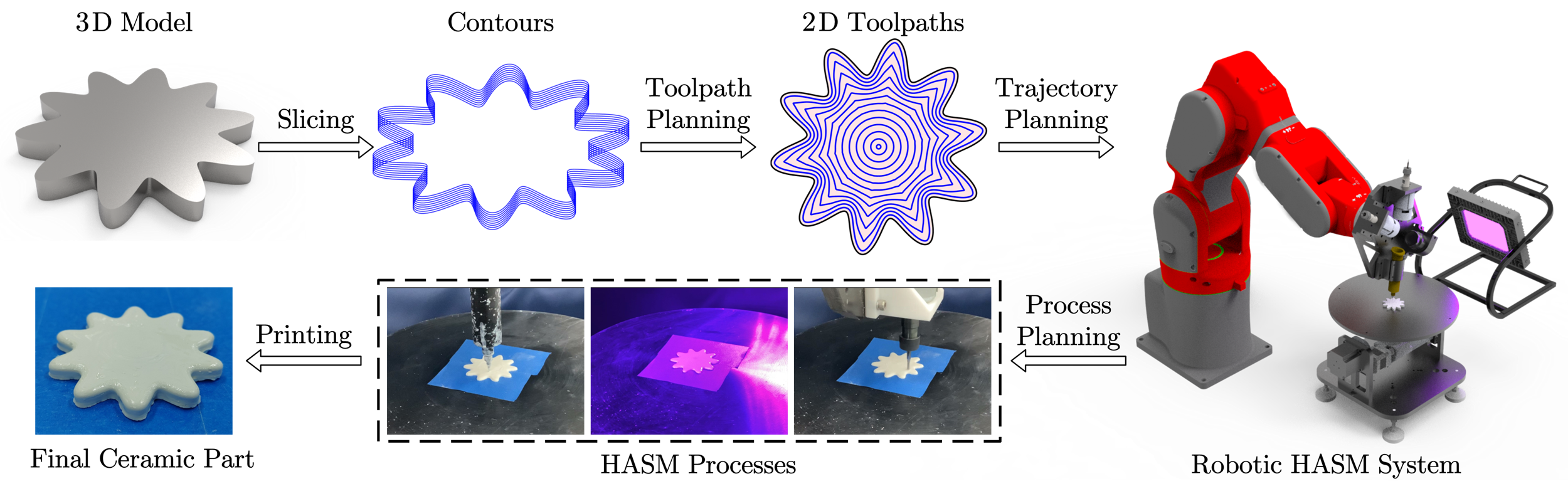

Compared to the classical contour parallel (CP) toolpath, IQOP reduces 58.1% of underfills, 55.4% of shape corners, and 7.6% of printing time. As shown in Figure 3, where a self-built extrusion-based robotic AM system is applied.

Figure 3. Real-world AM experiments.

-

Yunan Wang, Chuxiong Hu#, Zeyang Li, Zhirui He, Shiwen Lin, Yushuo Wang, Shize Lin, Jichuan Yu, Zhao Jin, Yu Zhu

Robotics and Computer-Integrated Manufacturing, 2025

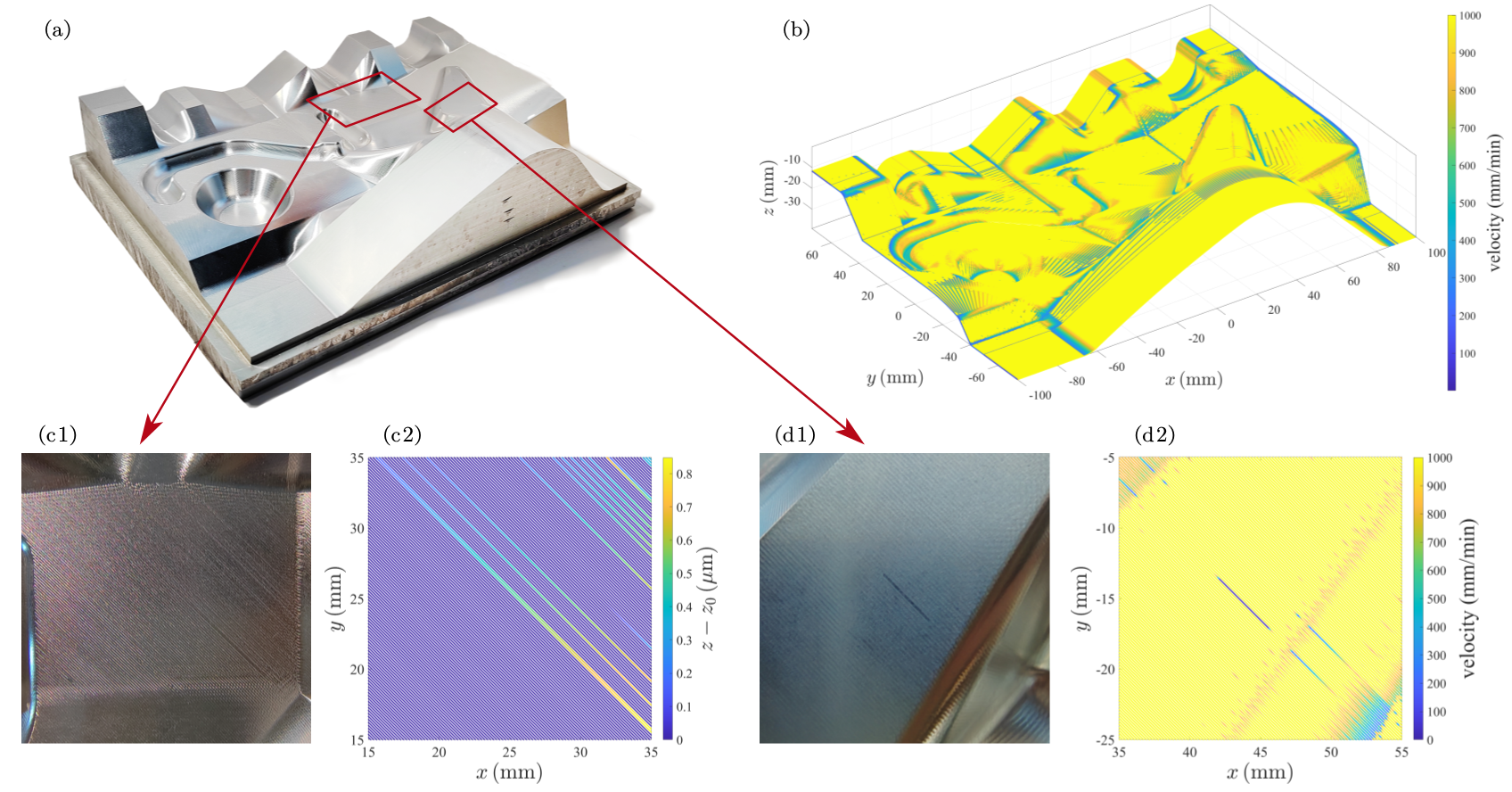

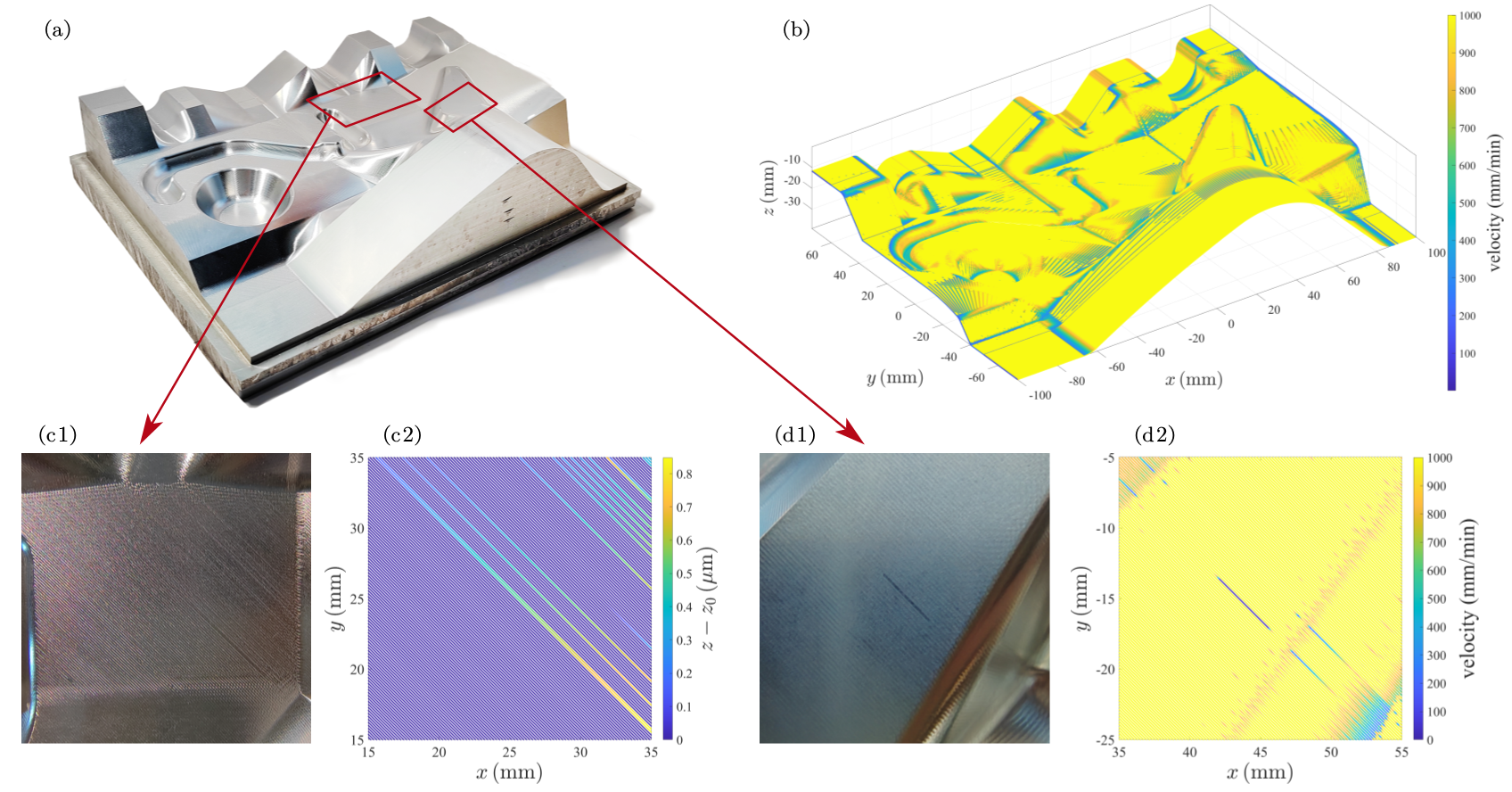

Path smoothing and trajectory planning are universally applied in computer-numerical-control (CNC) machining to avoid natural discontinuity of tangency and curvature at the junctions of G01 blocks. However, most existing methods primarily focus on path-centric indicators that consider the toolpath as a continuous curve, such as contour error and manufacturing efficiency, neglecting the global machining quality and failing to avoid surface inconsistencies, such as single tool marks, as shown in Figure 1. This paper establishes a theoretical framework to evaluate the global continuity of toolpaths and trajectories, proposing consistency as a surface-centric evaluation that considers toolpaths as a surface in CNC machining. In this paper, the consistency is defined as similarity between adjacent toolpaths and trajectories when facing similar input fold-paths in single-point milling. The consistency of four typical existing methods representing a broad category of typical approaches is investigated based on the developed theory.

Figure 1. Consistency and single tool marks in a Mercedes-Benz mold.

Conference Paper

-

Jerk-limited oscillation-free feedrate scheduling under non-stationary boundary conditions

Yunan Wang, Chuxiong Hu#, Jichuan Yu, Shize Lin, Zhao Jin, Jizhou Yan

IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Hangzhou, China, 2025

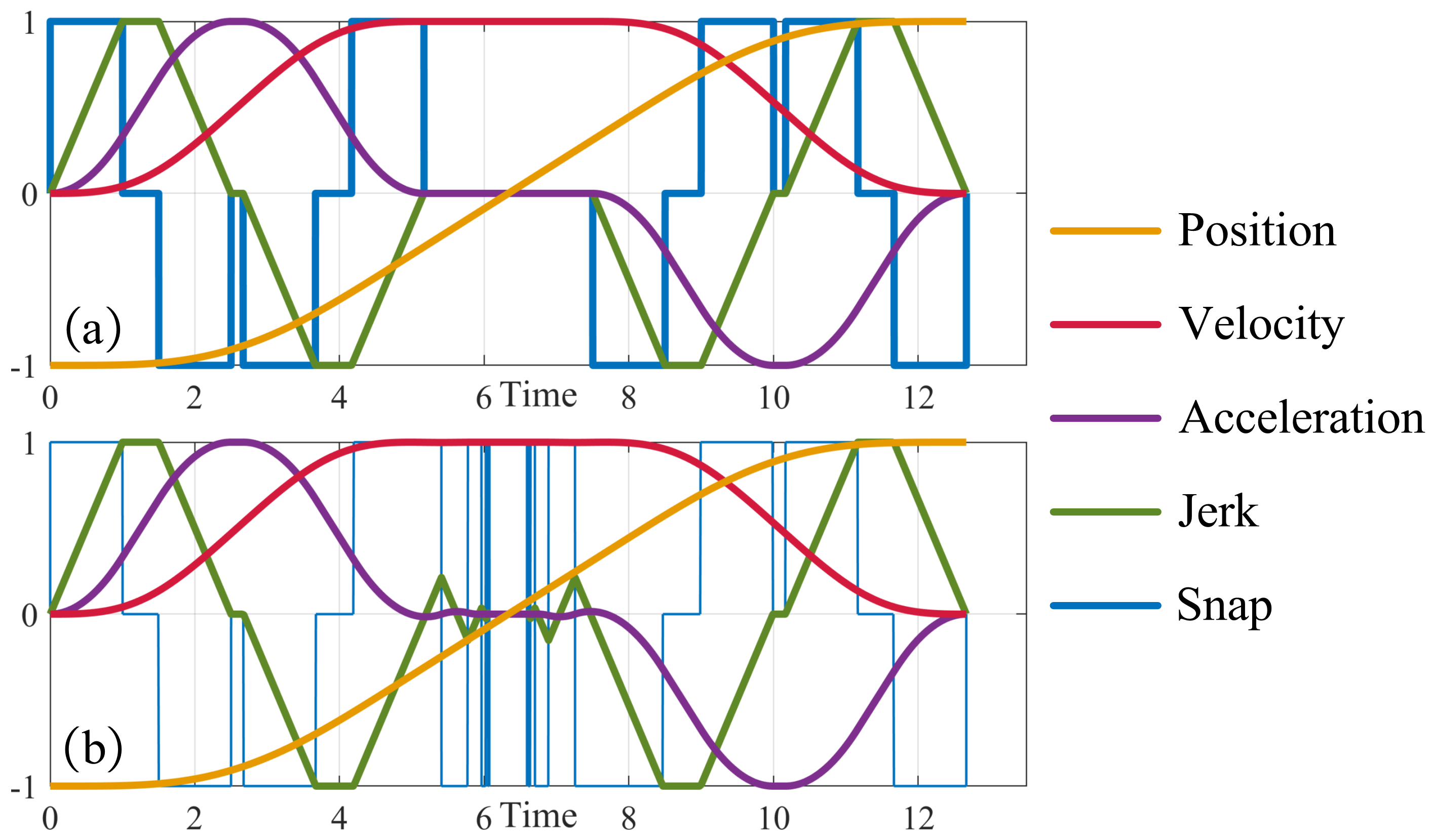

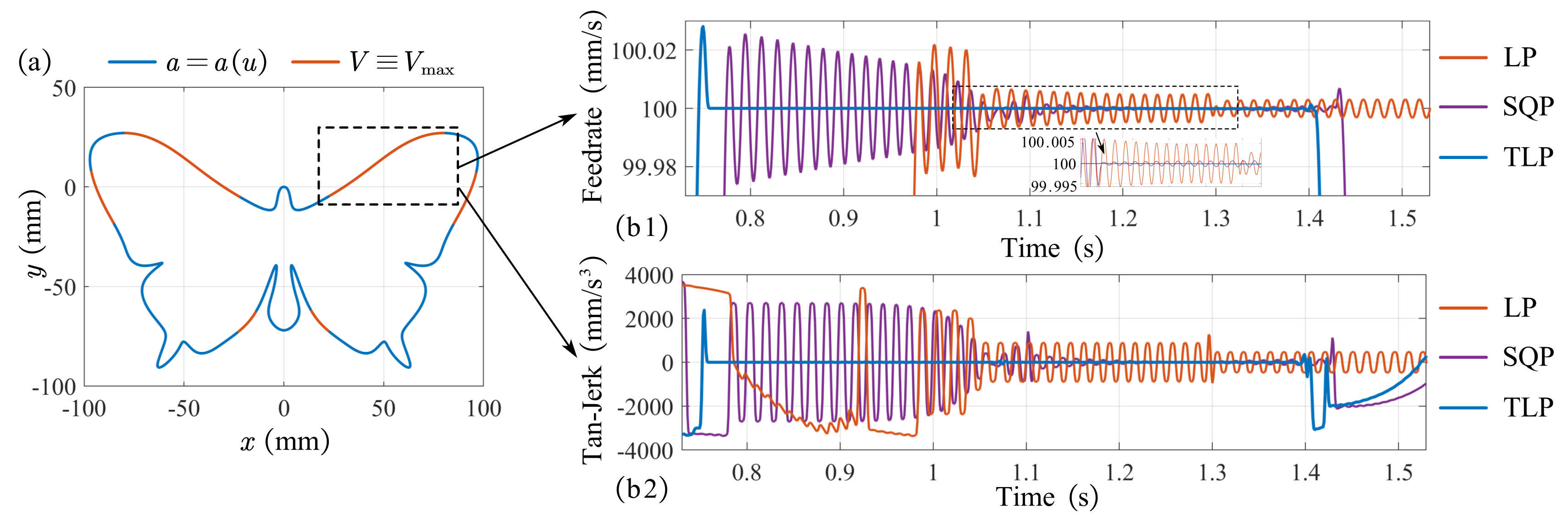

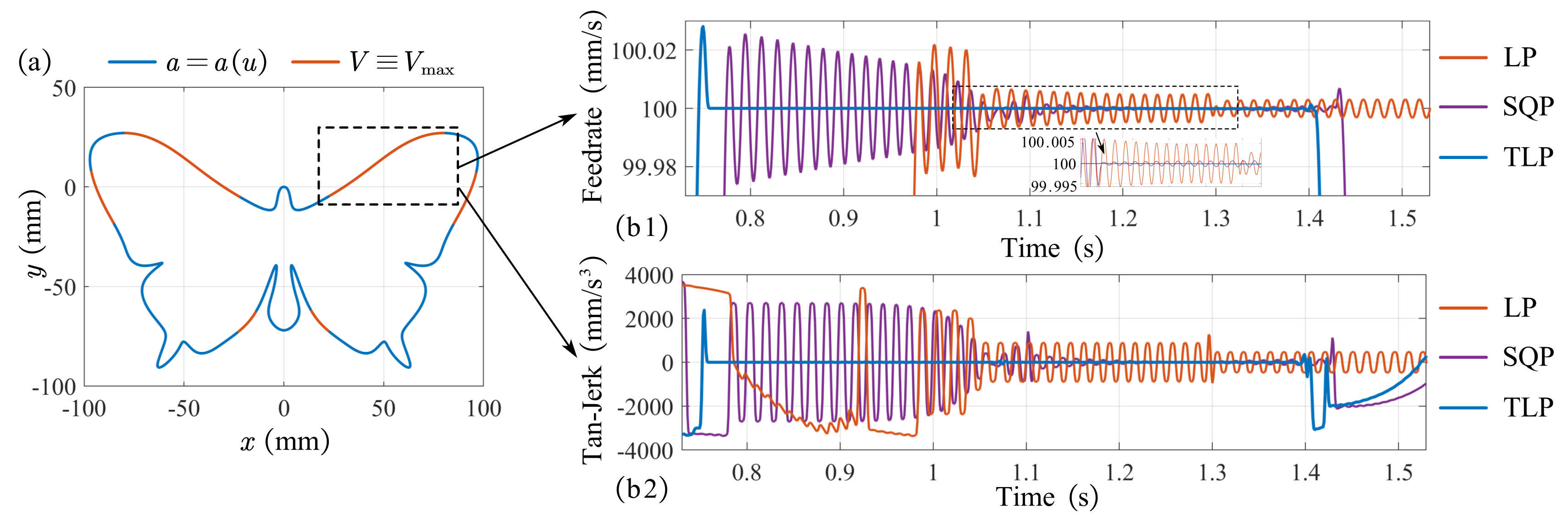

Feedrate scheduling has significant impacts on motion efficiency, equipment vibration, and machining quality in robotic manipulation and computer numerical control machining. As the most effective methods for jerk-limited feedrate scheduling, however, optimization-based approaches face challenges such as high computational cost, artificial infeasibility, and feedrate oscillations. This paper proposes a triple linear programming (TLP) method for solving the non-convex 3rd-order problem. To avoid artificial infeasibility caused by convexification, an incremental linearization method (ILM) is developed to generate a feasible solution under non-stationary boundary conditions. Feedrate profiles are further adjusted to eliminate the oscillations caused by the discretization. In experiments on machine tools and robotic manipulators, the proposed method saves more than 10% of motion time than existing linear programming methods and reduces computational time by more than 80% than baselines based on sequential quadratic programming with better time-optimality. Furthermore, the proposed method outperforms baselines regarding feasibility and feedrate oscillations, as shown in Figure 1.

Figure 1. An example of oscillation-free profile.

-

Slice extension for high-quality hybrid additive-subtractive manufacturing

Yunan Wang, Chuxiong Hu#, Ze Wang, Shize Lin, Ziyan Zhao, Yu Zhu

49th Annual Conference of the IEEE Industrial Electronics Society (IECON), Singapore, 2023

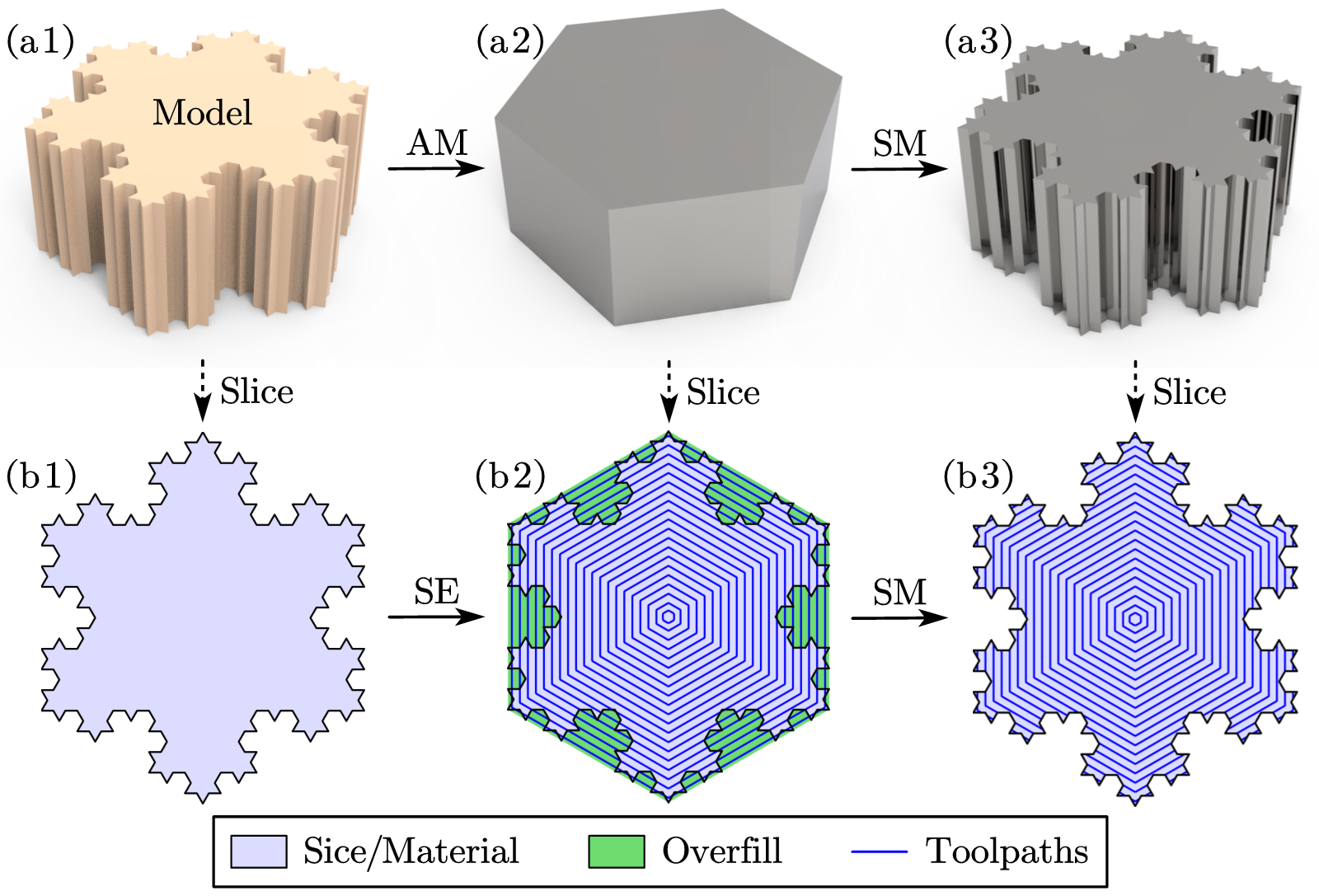

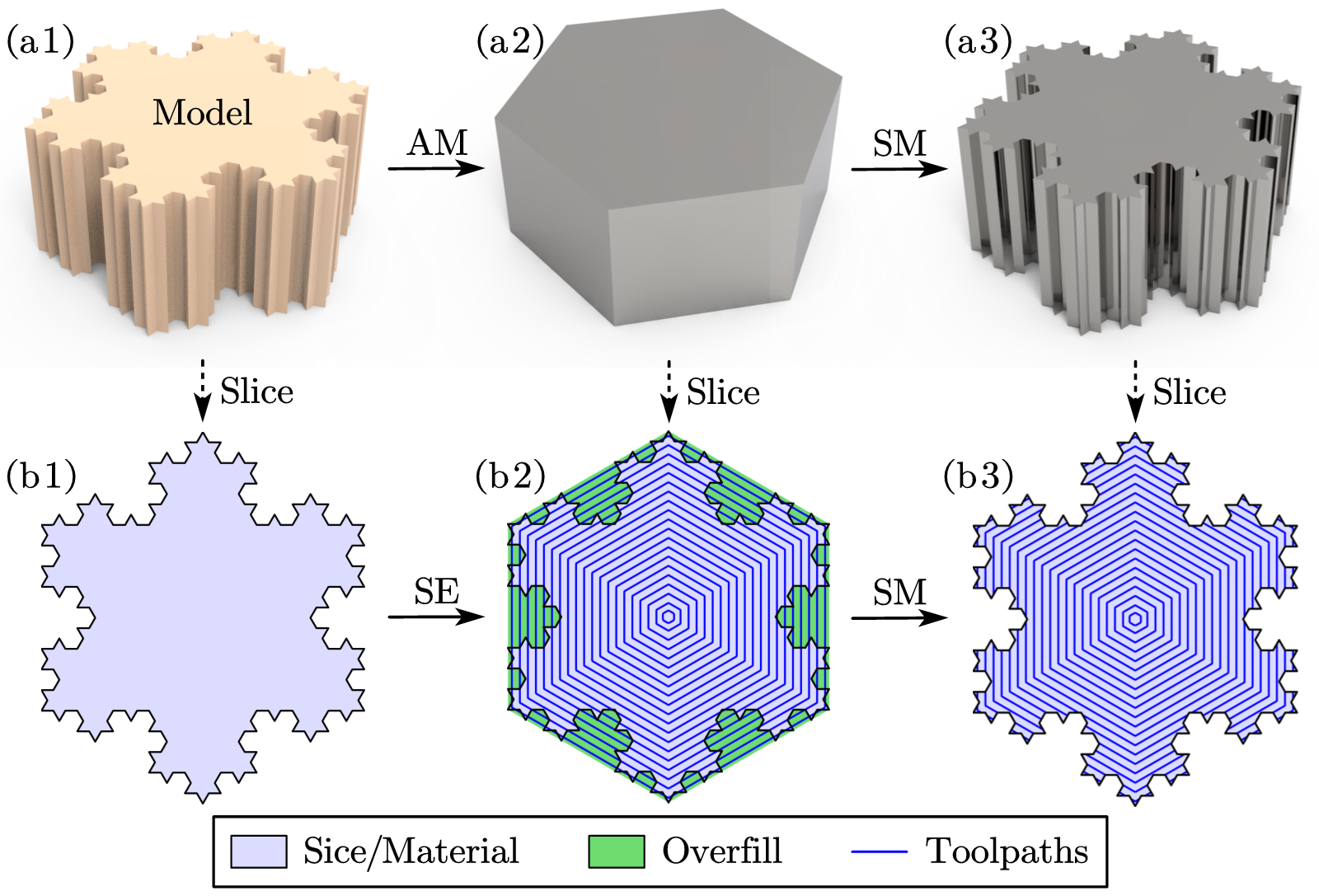

The additive manufacturing (AM) process has a significant influence on manufacturing quality and efficiency in HASM. However, few process planning methods exist utilizing the interplay between different processes in HASM. This paper proposes a slice extension (SE) method for HASM, the key idea of which is to print an extended slice in the AM process and guarantee the final geometric accuracy in the subtractive manufacturing (SM) process, as shown in Figure 1. The computational process of SE is similar to the inward IQOP.

Figure 1. Overview of slice extension.

Simulation experiments indicate that the proposed SE method achieved an 81.5% lower underfill rate than the conventional method, i.e., the widely-used contour-parallel (CP) method in the industry, with limited extra materials on average. The toolpath smoothness is also improved, as shown in Figure 2.

Figure 2. Slice extension for some slices.

-

Learning latent object-centric representations for visual-based robot manipulation

Yunan Wang, Jiayu Wang, Yixiao Li, Chuxiong Hu#, Yu Zhu

IEEE International Conference on Advanced Robotics and Mechatronics (ICARM), Guilin, China, 2022

Best Conference Paper Finalist

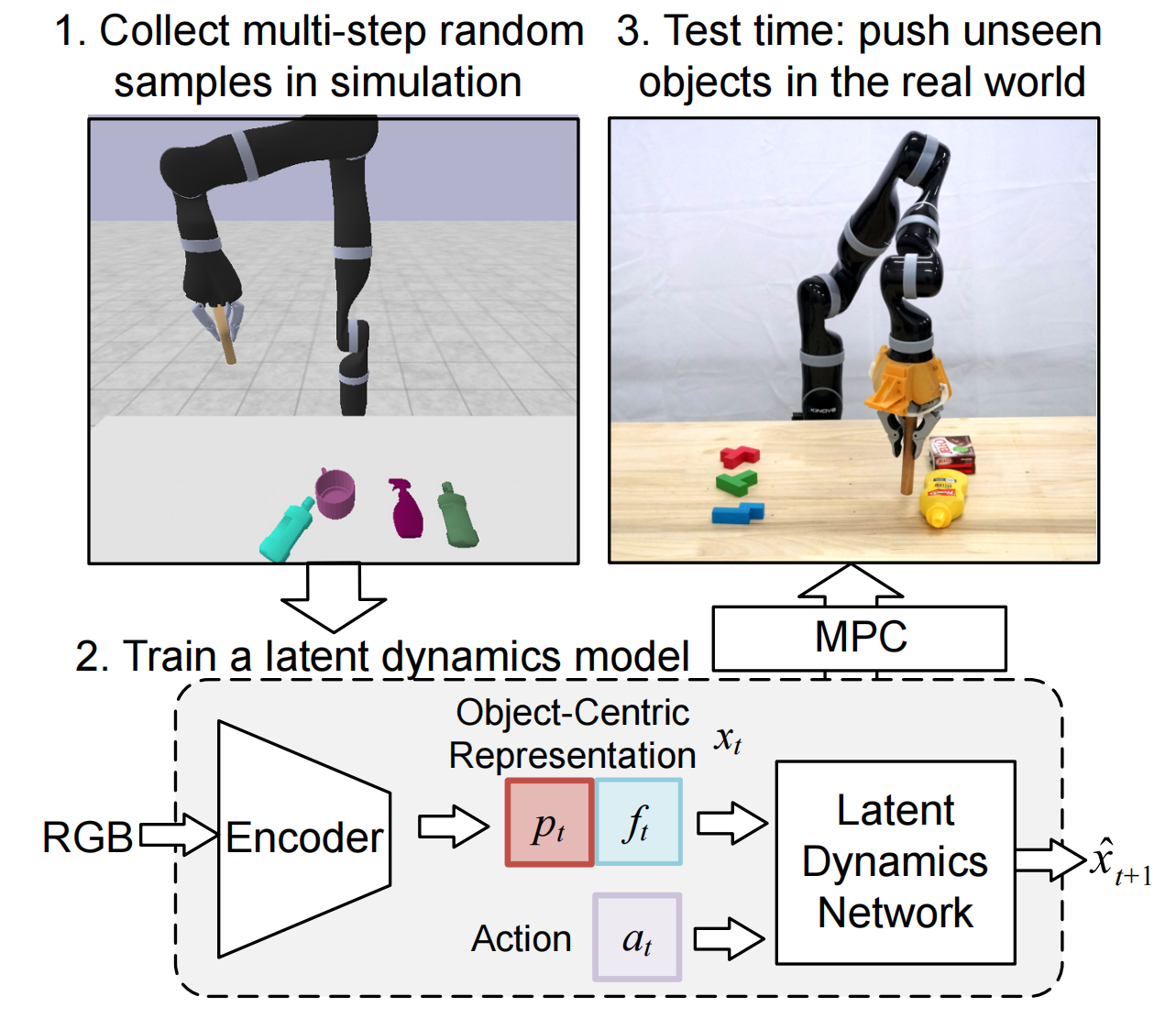

For multi-step robotic manipulation, it is important to predict the future state of the object conditioned on the applied action, especially from raw RGB images. A learning latent object-centric representation dynamic neural network (LOR-DNN) is shown in Fig. 12. We use a conditional variational autoencoder framework (CVAE) to map the high-dimensional RGB images into low-dimensional latent state space, where the state prediction is trained unlabeled. Then, a sample-based model prediction control (MPC) planner is applied to push the objects to the assigned goal positions. The model is trained based on self-supervised random interactions in simulation, while generalizing to pushing objects unseen before in the real world.

Figure 1. Overview of LOR-DNN.